By Dr. Grant M. Saxena, Ph.D.

History from Motorola Inception

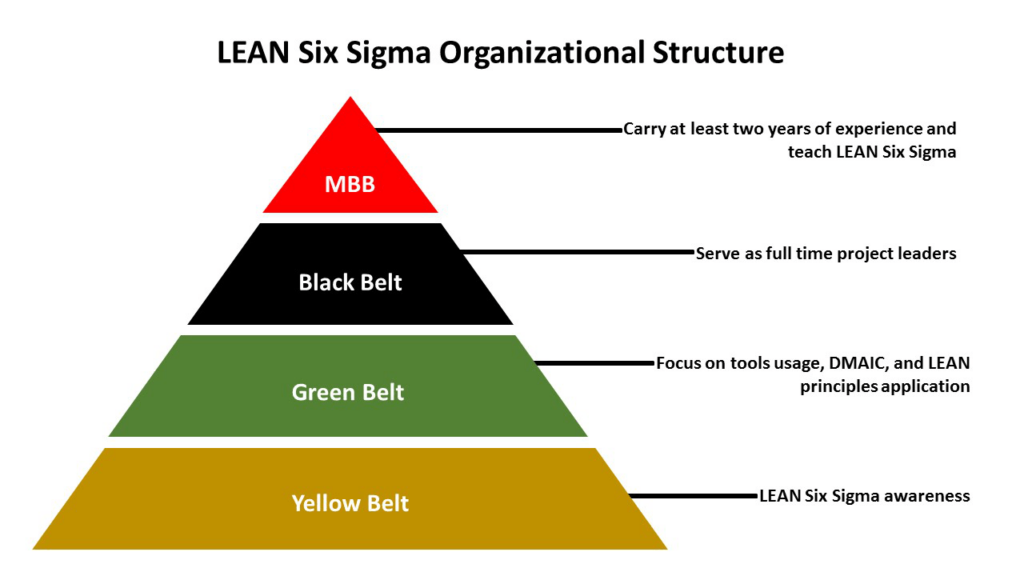

Few people know the history of Six Sigma, but when a business is struggling, Six Sigma is a very sought-after powerful tool that can improve processes. Companies are looking for Six Sigma Belts, which are individuals who have been trained in all or part of Six Sigma, to help them improve their business performance. Six Sigma was created by Bill Smith in the 1980s, as the 80s were ending. He was working at Motorola at the time and needed a quality management tool to increase business performance. He set about developing the method and spent all of his energy on what would be the future in quality management. Smith was supported by Bob Galvin (the CEO at Motorola), which made his job easier. Motorola applied the method company wide after Smith was done. Motorola was awarded the Malcolm Baldrige National Quality Award 1988 for its new process. There are many ways to organize your lean six sigma process management tool. This award is given to organizations that have demonstrated operational excellence in a variety of sectors.

Jack Welch Made Six Sigma Famous

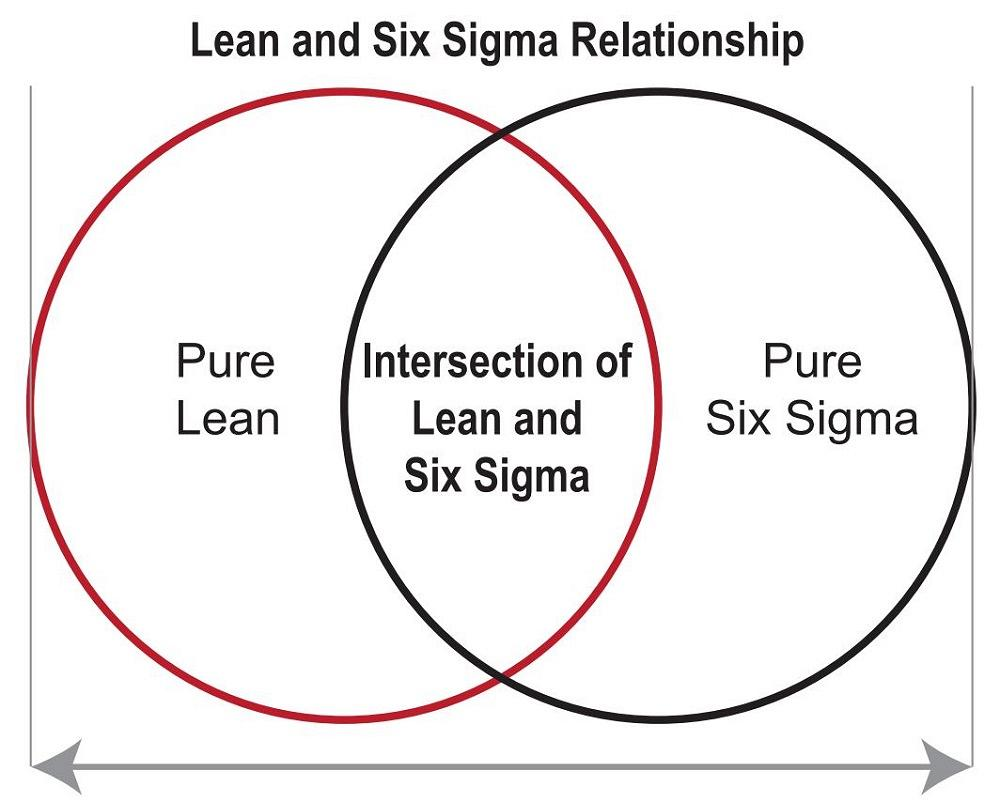

In the 1990s Jack Welch (the chairman of General Electric) adopted Six Sigma in his company. The company developed the method and linked it to executive compensation and return on invested (ROI). In GE’s annual reports, they showed that Six Sigma implementation had financial benefits. To improve their business operations, corporations on the Forbes Fortune 500 list began to implement Six Sigma. Jack Welch said, “Six Sigma changed the DNA of GE.” Six Sigma draws inspiration from LEAN. LEAN is a production method aimed primarily at quality management methods. Although it might seem like Six Sigma and LEAN could be considered rivals, they are complementary. Combining the two can produce unmatched business performance benefits, known as Lean Six Sigma. LEAN is a hands-on approach that removes non-value-adding tasks and improves efficiency. Six Sigma aims to decrease variability in organizational processes to minimize the likelihood of defects aka Muda (無駄).

The Synergy between LEAN and Six Sigma

LEAN has been around longer than Six Sigma, and its roots are in Japan’s Toyota Production System (TPS), which was established in the 60s. LEAN thinking is also rooted in the Arsenal of Venice, which was established in the 1450s. Henry Ford, who fully implemented LEAN thinking in his business operations, was the first to apply it to practice it. Boeing adopted Six Sigma in its 1993 manufacturing process. This made it even more popular. Boeing continued to invest in the method until it was successful, even though its initial attempts were unsuccessful. Six Sigma is still a new concept in business. Many companies around the globe are still trying to improve Six Sigma to improve their business efficiency through process improvement. Six Sigma and Lean, which were recently revived, have made a lasting impression on history.

Lean Six Sigma (LSS) and Artificial Intelligence (AI) have emerged as two of the most impactful methodologies and technologies in the modern business world. While Lean Six Sigma focuses on waste reduction, consistency, and efficiency, Artificial Intelligence drives automation, predictive capabilities, and cognitive intelligence. Together, they are poised to revolutionize data science and system improvement, beckoning profound future applications.

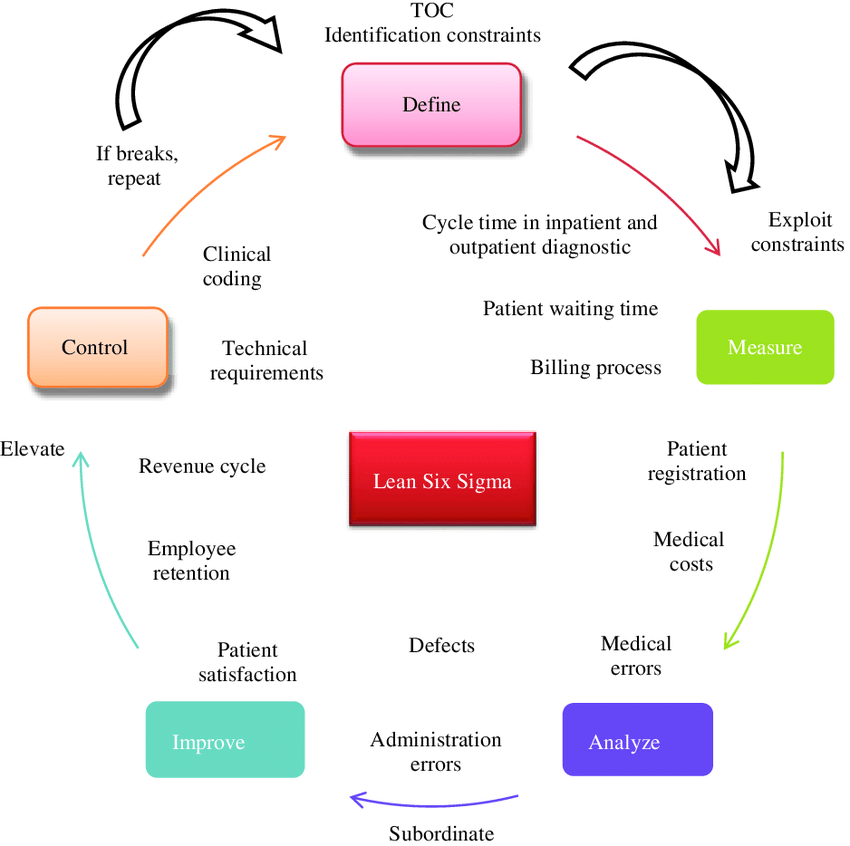

Lean Six Sigma combines Lean Manufacturing principles, primarily aimed at waste reduction, and Six Sigma, a data-driven approach aimed at reducing process variability to improve quality. Lean Six Sigma’s ultimate goal is to bring about improvements in process performance, reducing error rates and streamlining processes, thereby increasing profitability, improving customer satisfaction, and enabling long-term business growth.

Artificial Intelligence: A Phenomenal Disruption

Artificial Intelligence, on the other hand, entails the creation of systems or applications that exhibit human-like intelligence, capable of learning, problem-solving, decision-making, and understanding complex concepts. AI has emerged as one of the most transformative technologies of the 21st century, paving the way towards accelerated digitalization, more superior data analysis, and highly sophisticated decision-making processes.

Lean Six Sigma for Artificial Intelligence

Integrating Lean Six Sigma with Artificial Intelligence can have profound implications on data science, system improvement, and waste reduction, driving higher efficiencies and business growth. Lean Six Sigma methodology applied to the design, implementation, and improvement of AI systems can streamline processes, enhance quality and ensure more consistent, reliable outcomes.

Applying the principles of Lean to AI entails identifying and eliminating wasted efforts in the AI development and deployment process. The aim here would be to optimize the AI system performance by avoiding redundancy, streamlining workflows, and simplifying processes. For instance, Lean principles can be used to flag repetitive or unnecessary data cleansing, modeling, or validation steps in AI systems—effectively contributing to process speed and efficiency.

Six Sigma’s role in AI is quite similar but uniquely nuanced. By applying Six Sigma tools to AI processes, organizations can identify variations in processes and work to reduce them. When applied to AI, Six Sigma principles would hone the focus on data quality, consistent processes, and stable, reliable AI systems. This approach will result in more accurate AI models, greater predictability, and less variability in AI-driven decision outcomes, thus positively impacting the business’ bottom line.

Lean Six Sigma, when effectively combined with Artificial Intelligence, can have ground-breaking applications. By unlocking the full potential of data science, this combination can create highly efficient, intelligent, and waste-free processes.

Advantages of Incorporating Lean Six Sigma Principles in AI

The benefits of incorporating Lean Six Sigma in AI cover various aspects of organizational growth, such as:

1. Improved Quality and Accuracy: The Six Sigma principle, when implemented in AI, enhances the quality of output by identifying and reducing process variability. This results in superior data analysis and accurate decisions.

2. Enhanced Efficiency: Lean principles work to eliminate redundancies, streamline workflows, and optimize processes, thereby contributing to efficiency in AI development and deployment.

3. Superior Decision-making: With improved data quality and analysis, AI can drive better, data-driven decision-making across elements of the business.

4. Reduced Waste: The emphasis on waste reduction in Lean Six Sigma significantly reduces wasted efforts in AI operations leading to cost savings and improved productivity.

5. Robust AI Systems: By focusing on consistency, standardization and quality, AI systems can be made more robust and reliable.

Future Applications of Lean Six Sigma in Artificial Intelligence

While the integration of Artificial Intelligence and Lean Six Sigma is still in its nascent stage, the potential for future applications is immense.

In the field of data science, this integration could lead to the creation of automated, smart data analysis systems capable of delivering highly precise and consistent insights with minimal waste. It also paves the way for more sophisticated predictive modeling, risk assessment and decision-making in organizations.

In system improvement, Lean Six Sigma principles can be used to continually refine AI systems, reducing errors and improving quality. For instance, Lean Six Sigma techniques can be used to improve the accuracy of AI in image recognition, speech recognition and Natural Language Processing (NLP).

Additionally, the potential for waste reduction in AI operations through Lean Six Sigma offers immense opportunities for cost savings and productivity enhancements.

Conclusion

The combination of Lean Six Sigma methodologies and AI capabilities forms a powerful alliance that can offer unprecedented levels of system optimization, efficiency, and waste reduction. As more organizations begin to comprehend and leverage this potent combination, the stage is set for a new revolution in data science and AI-driven decision-making. We can visualize a future where AI will be leaner, more efficient, consistent, and reliable, driving transformative changes in the way businesses operate and grow.